Eagle Roof Tile and Vortex Hydra: working together to improve operational excellence in roof tile manufacturing.

Eagle Roofing Production, one of the leaders in the American concrete roof tile market, has always had as its goal of Operational Excellence in its manufacturing platform. Starting in 2018, Vortex and Eagle Roofing Products partnered to review the manufacturing process and determine the direction where automation could be best utilized to improve the operations. The initial focus being on reducing the hands-on labour-intensive job functions and then move on to improvements to “old technology”. Through strategic collaboration and the incorporation of some old and new ideas we have achieved some great results.

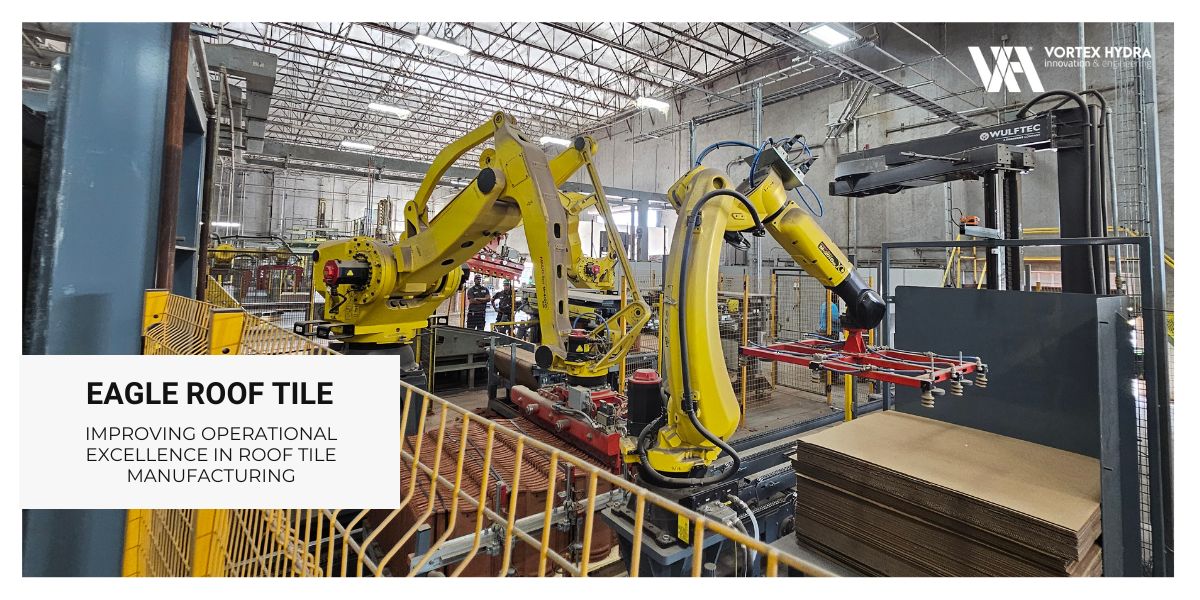

In just a few years we have been successful at completing several projects:

- Fully automatic robotic stacking lines in Rialto (CA), Phoenix (AZ) and Sumterville (FL)

- New servo driven cutting units in all production sites

- New aluminium molds including profile optimization in Stockton (CA), Rialto (CA) and Sumterville (FL)

A Partnership Built on Excellence

This collaboration between Eagle Roofing Products and Vortex Hydra represents a significant leap forward in our commitment to excellence and process efficiency. Vortex Hydra’s cutting-edge technology and long-term expertise in the design and implementation of high-performance production systems align perfectly with Eagle Roofing Products vision for transforming the future of roof tile manufacturing.

Why This Partnership Matters

The primary goal of this collaboration is to enhance the efficiency of Eagle Roofing Products production sites through automation operational improvements. By integrating Vortex Hydra’s state-of-the-art machinery and automation solutions, we are poised to achieve several key objectives:

- Increased Production Packager Efficiency: Vortex Hydra’s advanced systems will streamline production processes, reducing cycle times and maximizing output. This means faster production without compromising on quality.

- Enhanced Product Consistency: Precision is crucial in roof tile manufacturing. With Vortex Hydra’s technology, we will ensure uniformity and consistency across every tile produced, meeting the highest standards of durability and aesthetics.

- Reduced Operational Costs: Through automation and optimized processes, we anticipate a significant reduction in operational costs. This allows us to reinvest savings into further innovation and improvements.

- Sustainability and Eco-Friendliness: Our commitment to sustainability is reinforced by adopting energy-efficient machinery and processes. Vortex Hydra’s systems are designed with environmental considerations in mind, supporting our goal of minimizing our ecological footprint.

A Future of Innovation

This partnership is not just about immediate improvements; it is a strategic move towards a future of sustained innovation and growth. By leveraging the strengths of both companies, we are setting new benchmarks in the roofing industry and ensuring that both companies remain at the forefront of technological advancement.

Vortex Hydra thanks Eagle Roofing Products for continued support and trust. We are excited about the future and look forward to sharing more updates as we embark on this transformative journey.