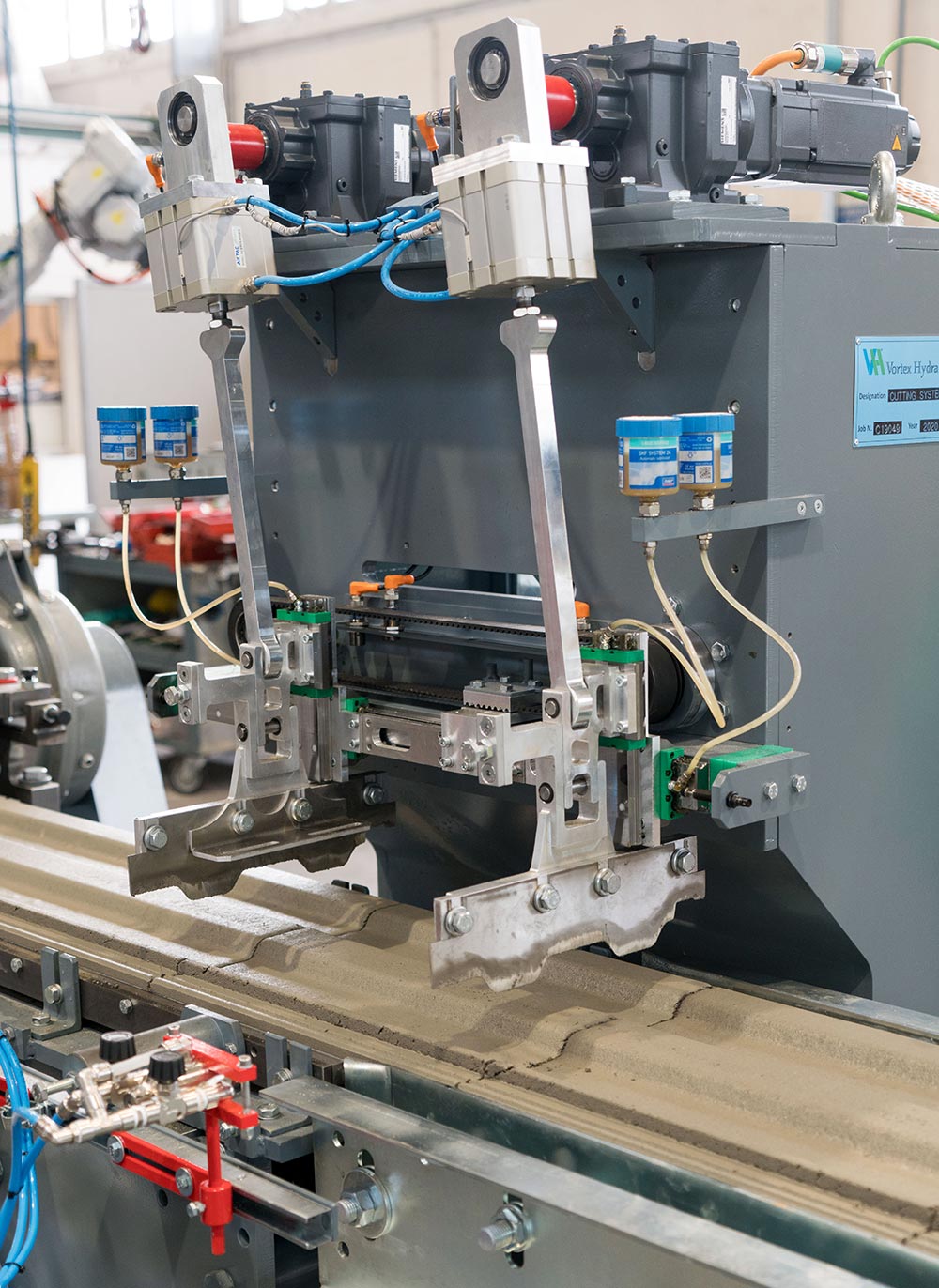

ELECTRICALLY DRIVEN CUTTING SYSTEM

Upgrades

Vortex Servo Drive Cutting Unit has the ability to cut the fresh extruded tiles with high precision, it is the result of experience gained in over 50 years of history, with all the excellence, quality, technology, innovation, modernity and durability that characterize the brand.

Main advantages deriving from the absence of mechanical coupling:

- Minimize the possibility of error during the “following phase”

- Detecting the position of the moulds with some OFF-SETS we are correcting the cutting and trim positions

- Longitudinal and vertical motions are perfectly synchronized by two electronic CAMs that reside in the PLC

- Mechanical: there is no need for systematic maintenance and the problems related to it are eliminated, such as a decrease in performance and in some cases the noise increase

- Less masses at stake – than involve less vibrations – reduced machine dimensions, inertial and wearing

- The design with electronic cams is facilitated by the presence of software

- Thanks to the electronic control it is possible to manage different functions and to get a very precise motion control, thanks to the interpolation of thousands of points

- Servomotors motors are characterized by compactness, excellent dynamic characteristics, good efficiency and high-power factor